Elan 46 LAS Glass Ceramic for Modern Glass-To-Metal Sealing

Elan Technology

Advanced Hybrid Glass Ceramic Technology

W. Nathaniel Horton, Ph.D. and Eric C. Skaar, Ph.D.

April 21, 2015

Elan 46 is a specialty belt process lithia-alumina-silica (LAS) glass-ceramic for use sealing to a wide range of metals with varied coefficients of thermal expansion (CTE) such as nickel-based Inconel or Hastelloy and stainless steel alloys. The Elan 46 LAS chemistry is specifically designed for a single ‘hump’ belt thermal profile whereby a preform is heated sufficiently to a melt glass which is capable of crystallizing lithium phosphate and upon cooling creating cristobalite nuclei. During a controlled cooling rate to an appropriate temperature the crystallization of lithium silicates and growth of cristobalite occurs so that the CTE can be tailored up to a high of approximately 200×10−7 in/in/°C.[1]

The ceramic technology used in glass-ceramics (G-C) are especially useful in glass-to-metal (G/M) sealing due in part to their ability to exhibit key properties of both a glass hermetic seal and a ceramic seal:

- Formability: The ability to flow the molten 46 glass into a complex geometry and then crystallize make it ideal when complex geometries are required.

- Hermeticity: The chemistry of Elan 46 lends itself to developing a strong chemical bond between the glass-ceramics and metal constituents. This bond may enhance both the strength and hermeticity of the seal, depending upon the production parameters.

- Strength: The ability of Elan 46 to crystallize during a simple belt process thermal profile contributes to the strength of the overall bulk glass.

- CTE Customization: The degree of crystallization of the ceramic phase(s) and morphology of Elan 46 drives the desirable ability to adjust the CTE according to the constituent material system.

- Production: Utilizing Elan 46 glass-ceramics instead of a traditional ceramic seal removes the need of an additional interlayer and accompanying production step.

- Durability: Elan 46 is a robust glass-ceramics capable of withstanding greater operational temperatures compared to conventional glass seals and is resistant to chloride attack.

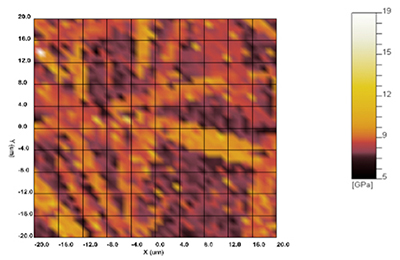

Fig 1. 2-D Transverse Hardness Map of Crystallized Bulk Elan 46

The lighter hue polymorph is illustrative of a harder crystalline phase.

Crystallization Study

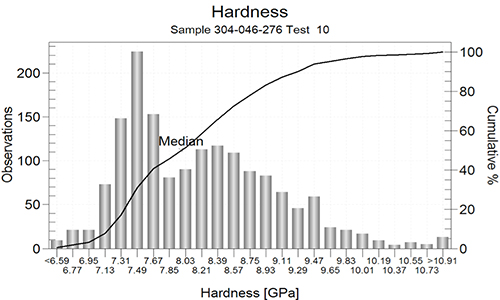

A crystallization study was performed to detail the nanomechanical properties of Elan 46, a LAS glass-ceramic, as a result of thermal processing.[2] A transverse 2-D hardness map of bulk Elan 46 with accompanying histogram were produced based on a typical belt furnace heat treatment: Rise to 980°C, flowed, and control cooled to allow crystallization.

Nanoindentation makes it possible to quantify intrinsic material properties of highly heterogeneous bulk materials or interfaces on a sub-microscale resolution and upscale the characterization to a real world macroscale application.

The hardness results from 1600 discrete nanoindentation sites manifest a bimodal distribution, signifying mechanically that a harder crystalline phase is present as well as a glass phase. Viewing 1600 hardness measurements as either a map or a histogram clarifies a distinction in bulk properties of the sub-microscale Elan 46 G-C that would be obscured with only 10–15 Vickers measurements.

Chart 1. Bimodal Hardness Histogram of Crystallized Elan 46

Application

High strength glass-ceramics, as illustrated here mechanically, feature the benefit of strengthening through crystallization of a second phase. This study documents an increase in degree of crystallization with less retained glass and overall crystal growth due to thermal processing. When working with G-C/M seals it is generally the goal to develop a higher strength via. a higher degree of crystallization with less retained glass and without coarsening the grains or significantly shifting the overall hardness to make the seal overly brittle.

References

[1] 46 Glass/Ceramic | ElanTechnology.com. Ceramic Glass Composite Material. Web. 6 Apr.2015 https://www.elantechnology.com/glass/glass-materials/46-glass-ceramic/

[2] W. Nathaniel Horton, Ph.D. Elastically Mismatched Interfaces as Related to Glass-to-Metal Seals for Applied Use Optimizing Functional Strength. Dissertation, Clemson University. Ann Arbor: ProQuest/UMI, 2014. (Publication No. AAT 3680707.)