Common Problems with

Glass-to-Metal Seal Design

Residual Stress

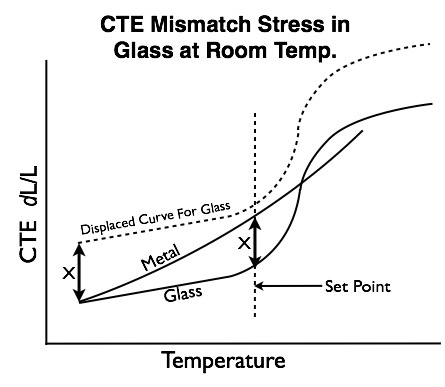

In a glass-to-metal seal design, once glass is flowed into the header geometry and cooled below the annealing point and the metal header contracts faster than the glass, internal residual stresses accumulate. Pure metals expand at a uniform rate, meaning their thermal expansion is a constant that is largely independent of temperature (provided no phase changes take place). Glasses on the other hand are temperature dependent and grow at an increasing rate, and are also dependent upon composition and the thermal history.

Failure: It’s All in the Cracks

- Ideally CTE mismatch and ensuing contraction exert compressive forces on glass.

- Cracks propagate perpendicular to the maximum stress within bulk glass.

- Post-mortem analyses are invaluable to optimize design and production.

In the idealized system of a compression seal, once glass has wet the metal and lowered just below the annealing/set point of the glass no significant stress relief by internal flow can take place. The metal header contracts, preventing the glass from following its path back to the original stress state and the glass’s expansion is displaced [displaced curve].

The proportion to which strains are induced, × is such that at the annealing temperature the expansion curve for the glass is shifted or displaced to intersect the curve for the substrate metal, i.e. stress free at the annealing temperature. Thus the proportional × value at room temperature is an estimation of the residual compressive stress in the glass.

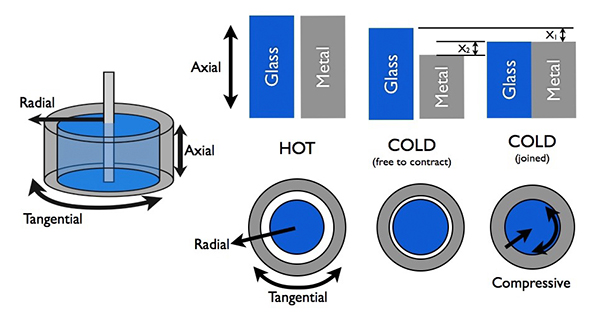

Consequently, strain due to differential expansion becomes permanent and three principal stresses are produced in G/M seals: axial, radial, tangential.

Axial, Radial & Tangential Stresses in Seal Design

Axial stresses act in the longitudinal direction, perpendicular to the diameter of the seal and parallel the primary pin/header axis; predominately these occur at the pin interface as the pin cools and shortens.

Radial stresses in the glass develop as the glass is constricted by the header. These compressive stresses act perpendicular to the axis of the seal and inward from the header.

Tangential or circumferential stresses act as a tangent plane to the outer radius of the seal or much like a hoop stress.

Caution: Excessive compression forces can give rise to detrimental tensile forces in an orthogonal plane of the glass.