Elan Technology: Glass & Ceramic Manufacturers

About Elan Technology

70 Years of Advanced Manufacturing

Elan Technology’s facility was constructed in 1997 and has a 90,000 sq.ft. footprint on 22 acres. Based in Midway, GA, our manufacturing facility was constructed specifically to create the most efficient arrangement for our manufacturing processes. Since 1998, when we were first registered under the QS-9000 standard, we have continued to develop and improve our quality system. As our businesses have evolved, we are pleased to announce that we have transitioned to ISO 9001:2015.

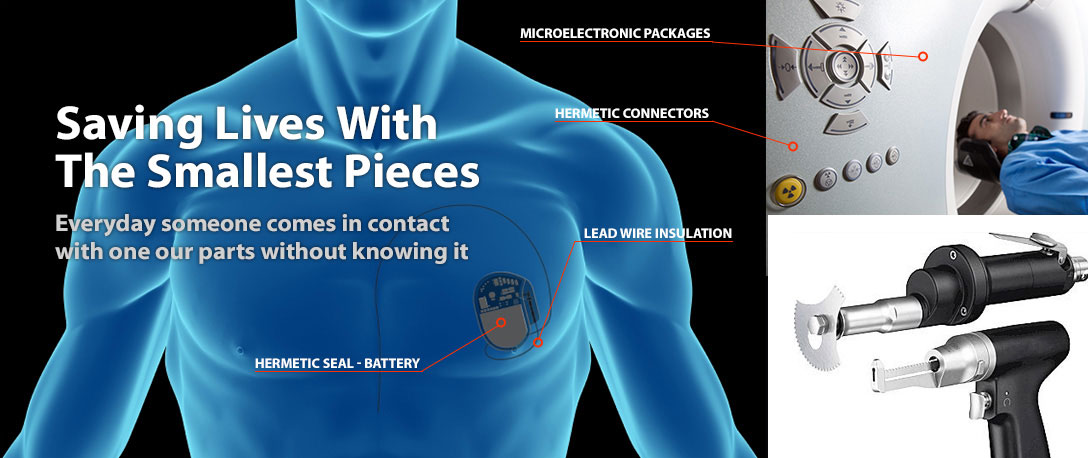

Glass Manufacturers

Technical Glass Products

As one of the largest technical glass manufacturers in the U.S., Elan Technology produces glass preforms from hundreds of proprietary electronic glass compositions to be used in a variety of applications which are commonly matched for glass-to-metal hermetic seals. Our glass materials are also offered as milled or spray dried powders. We supply glass preforms that are used in many industries, including the medical, defense, aerospace, lighting, automotive and micro-electronics fields. We provide customers with engineering support to assist with material selection and preform design. We also have the capability to develop custom glass materials compositions, depending on the specific customer application.

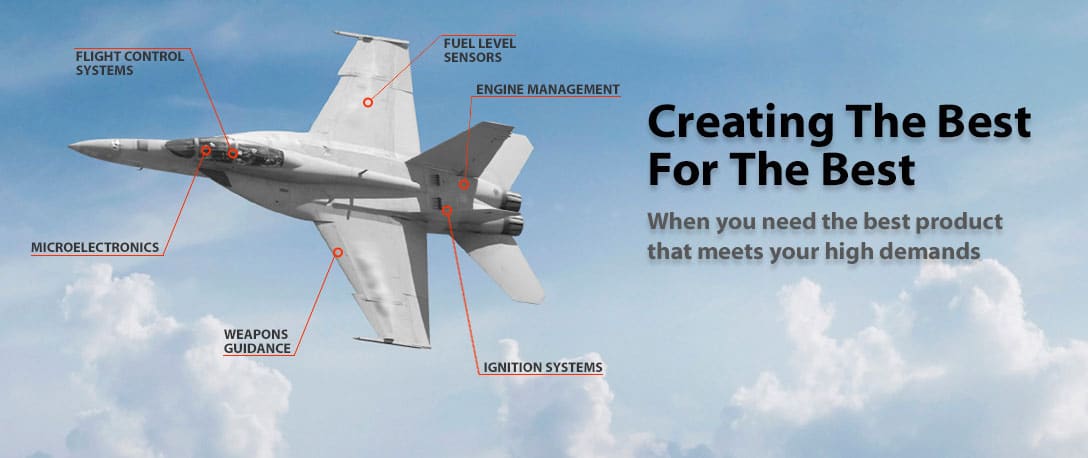

Ceramics Manufacturer

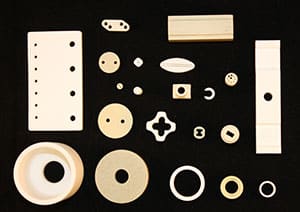

Advanced Technical Ceramics Company

Advanced technical ceramics are finding more uses in a variety of applications. As one of the leading ceramic manufacturers with over 70 years of experience, Elan Technology offers a variety of ceramic materials such as alumina ceramic, steatite, zirconia and cordierite. Our materials are used for wear-resistant parts, insulators and ceramic inserts for industrial applications. Whether for a demanding aerospace application, simple heat resistant spacer or a hermetic seal, we offer materials for a variety of applications and industries, and have full engineering support for material selection and component design.

Advanced Glass Ceramic Technology

Glass Ceramic Composite

Our special glass ceramic composite material has been adopted by many of our customers as a replacement for traditional ceramics in certain applications. Eliminating the need for brazing, the Elan 46 ceramic glass material provides proven performance, while lowering manufacturing costs. With a coefficient of thermal expansion from 110 to 220 (0°-300° (× 10-7 cm/cm/°C), the Elan 46 glass can withstand metallizing or brazing up to 700°C.

Spray Drying

Spray Drying Technology

We provide contract spray drying services to companies in a variety of industries for applications such as catalysts, pigments, detergents and ceramics. We process millions of pounds of material annually. Experienced engineers work with each customer to optimize the spray drying process in order to achieve the highest product quality. We support both small developmental projects, as well as large volume production. We offer a wide range of storage, mixing, packaging and atomization options, giving our customers the flexibility to customize the processes to meet any requirement.

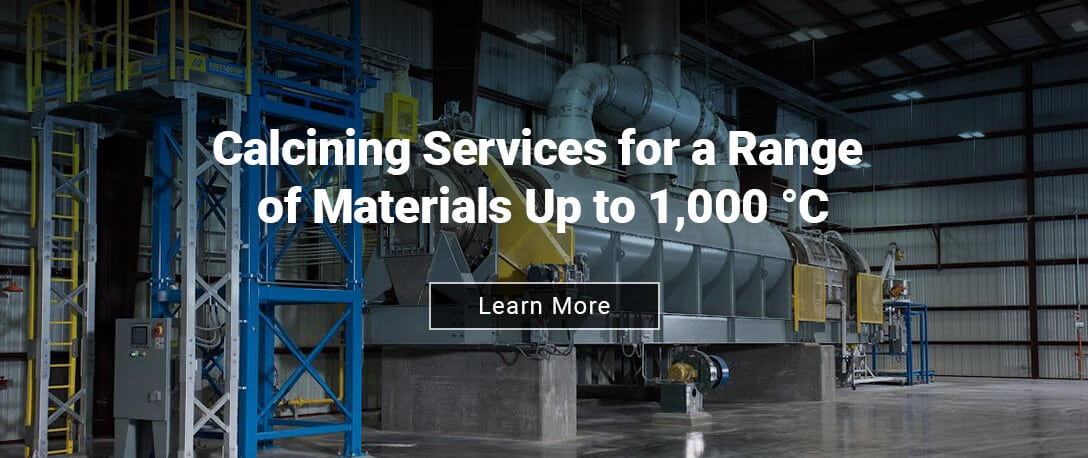

Rotary Calciner

Contract / Toll Material Thermal Processing Services

Our full-service rotary calciner offerings utilize highly-effective thermal processing treatments to process commonly calcined materials, including catalysts, clay, dolomite, silica, and more. Our toll processing services, including calcination, thermal desorption, and drying, provide solutions for a variety of advanced manufacturing applications.

Machining

Contract Machining Services

Elan Technology maintains a complete precise machine shop to support tool and die fabrication for all of our presses. In addition, our experts in machining technology assist our customers by providing expert machining services to other industries. We can machine most materials, including all tool steels, aluminum, ceramic, carbide and plastic.

Origin Glass

Art Glass

Origin Glass, a division of Elan Technology, produces high-quality borosilicate glass for artistic applications. Offering a wide range of brilliant colors, Origin Glass products are used by hobbyists and professional artists. Our Boro Stix can be found in art studios throughout the world. All of our colors are available from our various distributors located throughout North America and around the globe.